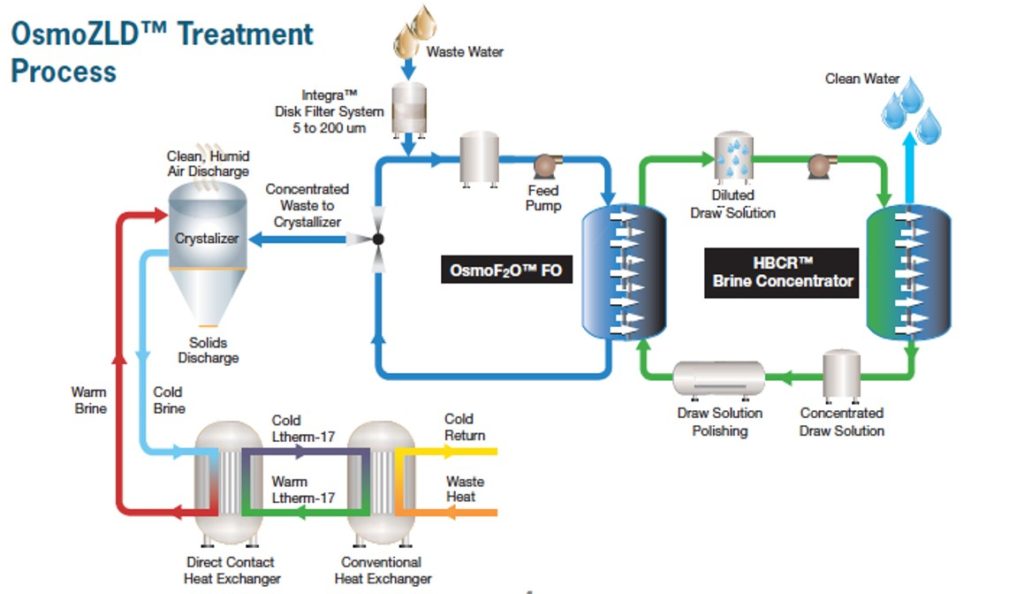

Zero Liquid Discharge (ZLD) technologies can help customers meet discharge and water reuse requirements by reclaiming high-quality water and generating solids (crystals) for further use or disposal. FTS’ OsmoZLD™ Process combines the technology of OsmoBC™ and Low Temperature Evaporative Crystallizer (LTEC.)

FTS delivers solutions that recover more than 95% of a plant’s wastewater while reducing the remaining brine as a product or solid. FTS uses innovative ZLD thermal and non-thermal technologies to help industry manage tough-to-treat wastewaters.

LTEC™ treats the concentrates from the OsmoF2O™ FO and HBCR™ Brine Concentrator system to realize zero liquid discharge. LTEC™ is engineered specifically for treatment of highly scaling wastewaters and reject brine streams to achieve zero liquid discharge. LTEC™ is a low temperature and atmospheric pressure technology capable of employing process waste heat as a ZLD thermal source while also providing high efficiency process cooling. The final product is water vapor to the atmosphere and salt solids.

Benefits

- Minimal cleaning required

- Lower capital and operation costs

- Robust and reliable even with varying wastewater streams

- 95% recovery with consistent flux rates

- Final FO concentrate can be < 10% of leachate feed

- No scaling, no fouling, corrosion-free operation

- Process waste heat used as the thermal energy source

- Enhanced process cooling

- Treats a wide range of wastewaters

- Does not require pressure vessels and associated heavy support structure and associated foundation constraints

- Does not require expensive and hazardous biocide

- Reduces or Eliminates the need for large evaporation ponds